What We Offer

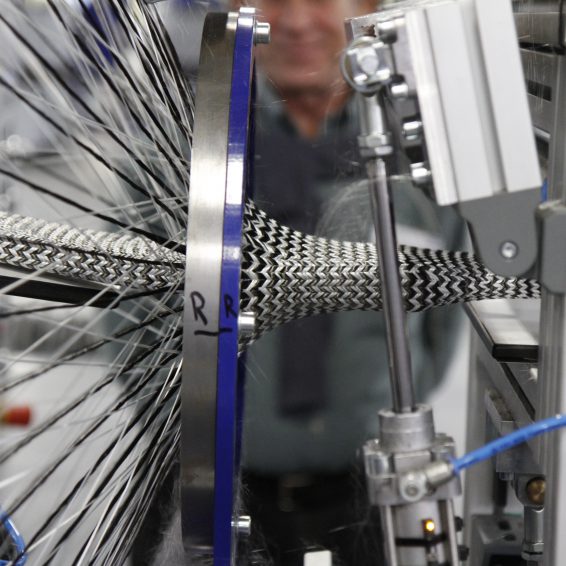

For each product an over braiding machine and yarn configuration can be selected to produce your optimum preform. Eurocarbon have 11 years of experience in over braiding and are able, with their R & D team, to do the total preform development. If a special braiding machine or extra equipment is needed, they can build it and we can offer a turn-key solution and transfer of know-how, so you can produce your own preforms. Preform developments and preform production can be done entirely in-house.

Datasheets are available on request.