What We Offer

Please refer to our technical data sheet for processing instructions or speak to a member of our technical team.

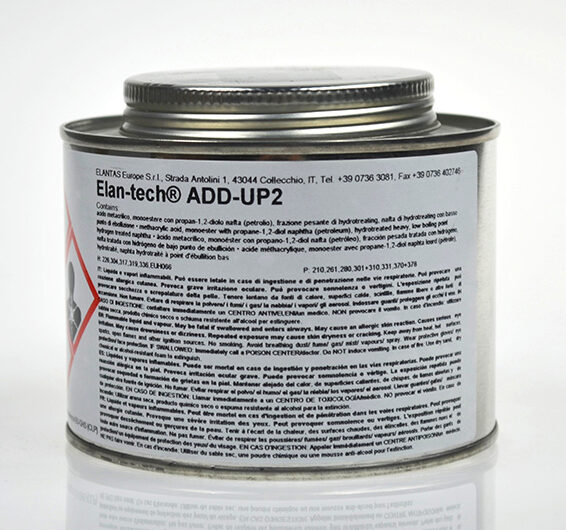

| Reference | Appearance | Flash Point | Density | Viscosity, dynamic | Applications |

|---|---|---|---|---|---|

| 99207-P0-AD-1 | Liquid, opaque | 32°C | 0.86 g/ml at 25°C | 10-20 mPa.s at 25°C |

To be added to the gel coat/resin. It provides a speed up in the curing of gelcoat and promotes a perfect adhesion of the Epoxy Resin applied immediately after. |