What We Offer

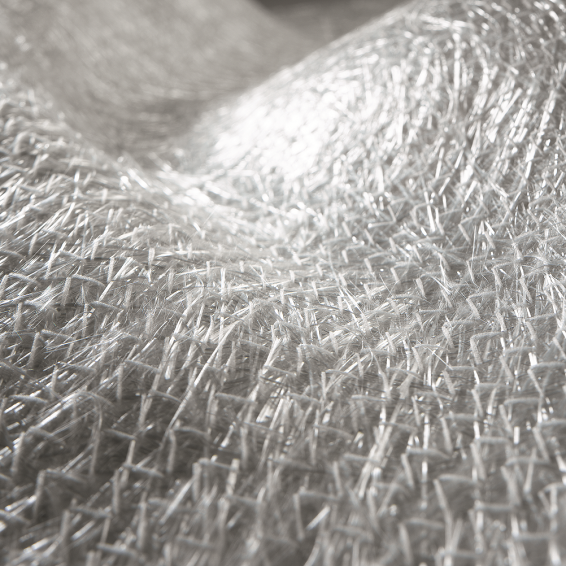

SAERcore and SAERcore MAX are both available in combination with SAERfix, which means that the mould filling time can again be drastically reduced. To achieve an optimum surface appearance for the finished component, SAERcore can be supplemented with an additional non-woven covering. On request, SAERTEX can also produce customer-specific kits that again significantly accelerate further processing.

| SAERcore | SAERcore with High-Flow | SAERcore MAX | SAERcore MAX with High-Flow | |

|---|---|---|---|---|

| Process | RTM, RTM Light Compression, Cold mould process | RTM, RTM Light Compression / Cold mould process / vaccum infusion | RTM, RTM Light Compression / Cold mould process | RTM, RTM Light Compression / Cold mould process / vacuum infusion |

| Components | SAERcore | SAERcore with High-Flow | SAERcore MAX | SAERcore MAX with High-Flow |

|---|---|---|---|---|

| CSM per layer g/m² | 150-1,000 | 150-1,000 | 150-900 | 150-900 |

| Flow medium* non-woven or knitted | PP13, PP18, PP20, PP25 | PP25HF, KP3, KP5 | PP13, PP18, PP20 PP25 | PP25HK, KP3, KP5 |

| Assembly | Stitched | Stitched | Stitched | Stitched |

| Multiaxial fabrics (UD, BX, BD, TX, QX) | - | - | Glass, Carbon, Aramid | Glass, Carbon, Aramid |

| Widths | SAERcore | SAERcore with High-Flow | SAERcore MAX | SAERcore MAX with High-Flow |

|---|---|---|---|---|

| Standards | 1,250 mm, 2,500 mm | 1,250 mm, 2,500 mm | 1,250 mm | 1,250 mm |

| Individual Tapes | 150-3,200 mm | 150-3,200 mm | 150-2,500 mm | 150-2,500 mm |

| Extras | SAERcore | SAERcore with High-Flow | SAERcore MAX | SAERcore MAX with High-Flow |

|---|---|---|---|---|

| Kits (from template or CAD file) | x | x | x | x |

| SAERfix | x | x | x | x |

| Surface fleece | x | x | x | x |

NS-CORE

| Data Sheet | Style | Width | Roll Length |

|---|---|---|---|

| NS - CORE 200/PP18/200 | NS - CORE 200/PP18/200 | 125cm | 60m |

| NS - CORE 300/PP18/300 | NS - CORE 300/PP18/300 | 125cm | 55m |

| NS - CORE 450/PP18/450 | NS - CORE 450/PP18/450 | 125cm | 50m |

| NS - CORE 400/PP25/400 | NS - CORE 450/PP25/450 | 125cm | 40m |

| NS - CORE 600/PP18/600 | NS - CORE 600/PP18/600 | 125cm | 40m |

| NS - CORE 600/PP25/600 | NS - CORE 600/PP25/600 | 125cm | 35m |

| NS - CORE HF 300/PP18/300 | NS - CORE HF 300/PP18/300 | 250cm |